SPL 1495 Sigatoka Ironsands Project

Sigatoka Ironsands Project

The Sigatoka Ironsands Project lies within SPL1495, on the south coast of Viti Levu, the largest island of Fiji. It is located approximately 80km south of Nadi and 120km west of the capital, Suva, and is near the town of Sigatoka. SPL1495 covers an area of 2,522.69 hectares on the plains at the mouth of the Sigatoka River, the river itself and an area offshore.

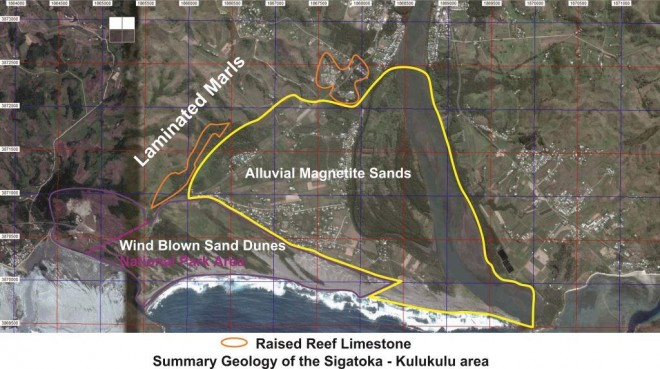

The satellite image above shows the main geological features of the Sigatoka area. The alluvial sands cover a down-thrown fault block and are underlain by a combination of marls and limestone debris. The Sigatoka River course was initially along the western margin of this alluvial plain and has migrated eastward, gradually building up the large washed sand deposits with the assistance of the prevailing southeasterly trade winds and ocean currents. Large volumes of sand containing magnetite have accumulated on the western side of the river mouth, as is evident in the satellite image.

The targeted sand comprises sediment that was eroded from magnetite-bearing volcanic and intrusive rocks inland carried toward the sea by the river. As the river neared the marine outlet, the action of wind, current and waves has produced concentrations of heavier minerals while removing clay-sized material. Exploration confirmed the presence of magnetite and other heavy minerals in the Sigatoka sand deposits, and exploration by Dome has now quantified an initial resource.

Magnetite as a source of iron for steel making, used in coal washing and in heavy marine cements so has plenty of potential markets. Its concentrates command a premium over the price of bulk iron ore because of its purity and use, for example, as a feedstock for specialty furnaces, in the recycling of steel and iron. The Sigatoka iron sand deposits contain other heavy minerals such as ilmenite as well as reclamation sand and gravel that add value.

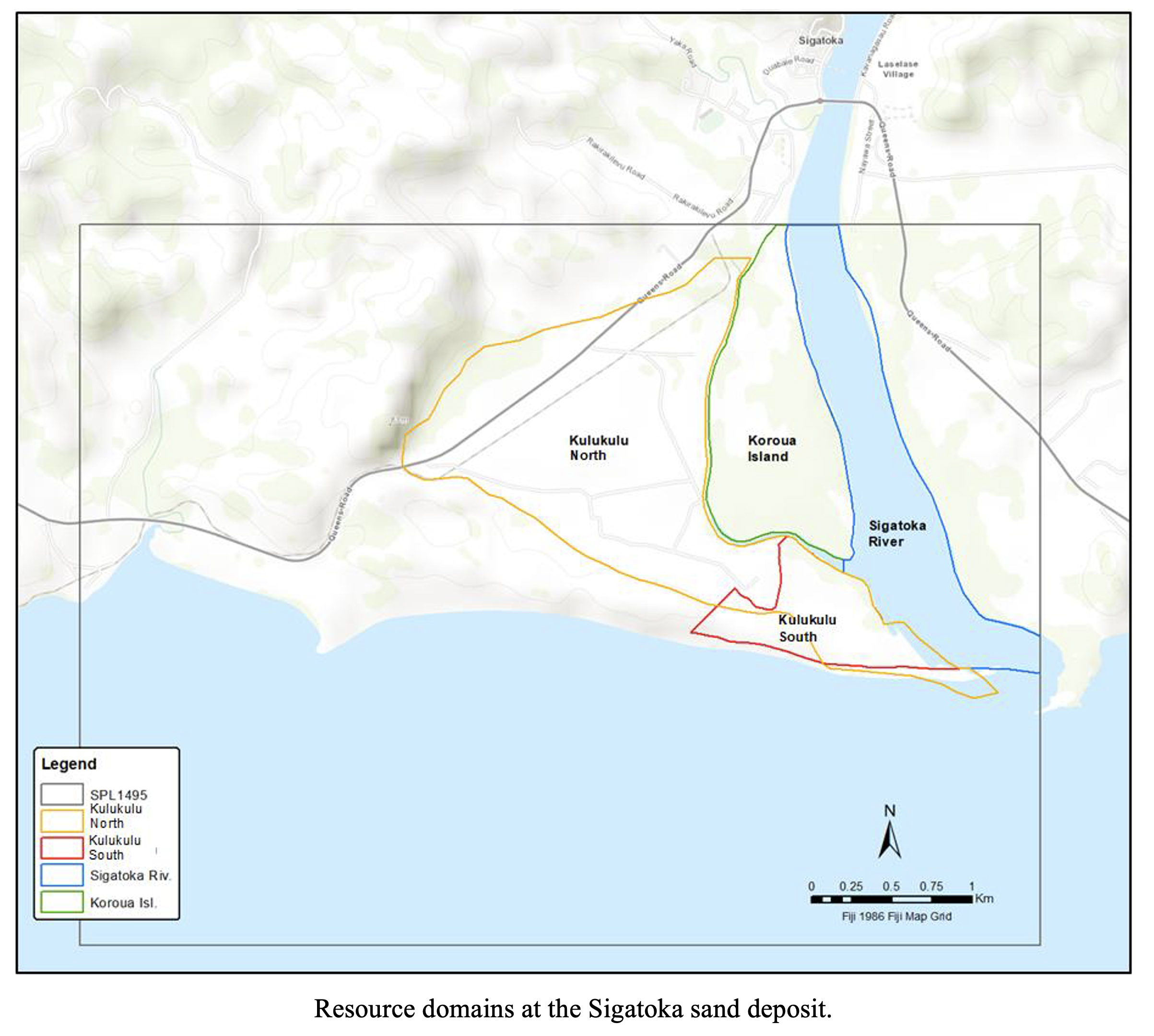

Based on exploration undertaken by Dome, a Maiden JORC 2012 Resource Estimate of 131.6 million tonnes was announced in October 2014, which included Indicated Mineral Resources of 25 million tonnes @ 11.6% HM at Sigatoka River, and Inferred Mineral Resources of 100.7 MT @ 17% HM at the onshore Kulukulu prospect and 5.9 million tonnes @ 11% HM at Sigatoka River (see ASX release dated 10 October 2014).

On November 5, 2020, the Company announced a third JORC 2012 Resource update as follows;

Revised Mineral Resources at Sigatoka

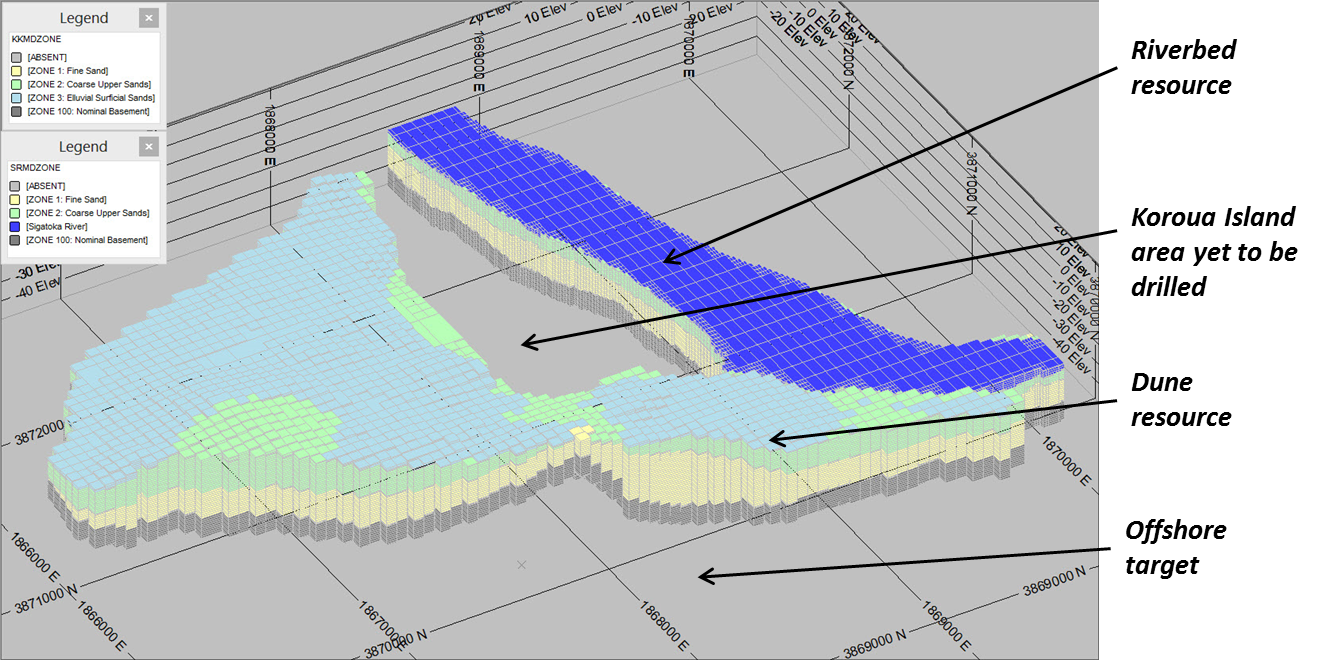

The total mineral resources at Sigatoka are now 189.3 million tonnes (Mt) at 12.7% heavy minerals (HM), with a cut off of 8% HM. This is made up of the following:

Kulukulu South:

A combined Indicated and Inferred Resource of 34.6Mt at an average grade of 20.2% Heavy Minerals and 12.9% Clay containing 7Mt of Heavy Minerals, which includes:

- An Indicated Resource of 34Mt at an average grade of 19.7% Heavy Minerals and 13.1% Clay containing 6.7Mt of Heavy Minerals of which 25% is MAG1 (300 Gauss) Heavy Minerals.

- An Inferred Resource of 0.61Mt at an average grade of 48.3% Heavy Minerals and 4.2% Clay containing 295kt of Heavy Minerals of which 25% is MAG1 (300 Gauss) Heavy Minerals.

Kulukulu North

The unclassified resource for the Kulukulu North area is now:

A total of 73Mt at an average grade of 17.4% Heavy Minerals and 6.0% Clay containing 12.7Mt of Heavy Minerals of which 14.8% is MAG1 (300 Gauss) Heavy Minerals.

Koroua Island

An Indicated Resource of 52.5Mt, at an average grade of 13.2% Heavy Minerals and 13% Clay, containing 6.9Mt of Heavy Minerals of which 23% is MAG1 (300 Gauss) Heavy Minerals.

Sigatoka River

A combined Indicated and Inferred Resource of 29.4Mt at an average grade of 11.4% Heavy Minerals and 6.7% Clay containing 3.3Mt of Heavy Minerals, which includes:

- An Indicated Resource of 23.9Mt at an average grade of 11.5% Heavy Minerals and 6.6% Clay containing 2.8Mt of Heavy Minerals of which 15% is MAG1 (300 Gauss) Heavy Minerals.

- An Inferred Resource of 5.3Mt at an average grade of 10.8% Heavy Minerals and 7.0% Clay containing 570kt of Heavy Minerals of which 14% is MAG1 (300 Gauss) Heavy Minerals.

In early December 2014 Dome received an Environmental Impact Assessment report prepared by independent environmental specialists, Corerega Environmental Consultants. The report concluded that “The proposed mining, dredging and mineral extraction development project is likely to have significant economic benefits to the local area, the region and the Country of Fiji and local residents are likely to benefit from the increase in productivity of land, river and marine environment and through job opportunities”.

In October 2015 formal approval was received from the Fiji Department of Environment of the Environmental Impact Assessment (EIA) report on the Sigatoka Project (see ASX announcement dated 15 October 2015).

Going forward

Dome is now proceeding expeditiously to obtain a Mining Lease. This will require the submission of a Definitive Feasibility Study (DFS) as well as an updated Environmental Impact Assessment (EIA) based on the mine plan and treatment process to be undertaken to Government.

In September 2021, a 15-20 tonne bulk sample representative of the Sigatoka deposit in the area where mining and processing is proposed to commence was shipped to IHC Mining’s metallurgical laboratory in Queensland for large-scale pilot plant testwork as a prerequisite top the DFS.

During October 2021, the Company engaged Flagstaff PCM Pty Ltd (Flagstaff) to provide engineering services and overall management of the DFS and EIA programs. Following requests for competitive bids on the main components of the DFS, Flagstaff recommended engineering and environmental experts to complete the major components of the DFS including the mine plan, plant package, financial model, market studies and geotechnical investigations. They also recommended experts to undertake the marine, river, land and societal inputs to the EIA. These programs are now well underway and expected to be completed by the end of 2022.

Dome proposes to mine and extract the magnetite, ilmenite and other heavy minerals from the sands in the Sigatoka River. In addition, subject to Government approvals, the processed sand and gravel tailing that is not required for local use after removal of commercial heavy minerals may be sold for land reclamation purposes adding further value to the iron sand mining operation.

The Sigatoka iron sand mineralisation is easily accessible and mining is expected to employ low-cost dry mining and dredging methods commonly used in the mineral sand mining industry. The magnetite and other heavy minerals of value are recovered as concentrates by various combinations of gravity, electrostatic and magnetic processes that are already widely used in the mineral sands industry. Once the Definitive Feasibility Study has confirmed the deposit to be economic to mine, development and concentrate production can occur very quickly.

There are several features of the mineralised area at Sigatoka that should be economically advantageous when mining commences. In the first instance, the organic overburden or soil layer is generally less than 1m in thickness and is immediately underlain by magnetite-bearing, orange to brown beach sand. Holes drilled to date have extended from the far north of the deposit, at its most inland development, to the river bank near the sea and show a general thickening of sand from 10-12m inland to greater than 35m of sand toward the south and east (i.e. toward the present day Sigatoka River channel and the sea).

Another important feature of the sand from an economics point of view is its very low clay (slimes) content, which was 4.8% in the bulk sample and average less than 8% in all holes drilled to date. This means the washing of the material through the processing plant will likely create far less slimes, making the management of tailing and wash water easier and less costly.

The processing operation uses fresh water only so will not introduce contaminants into the local environment. Aside from the economic benefits the mine will bring to the local community and to Fiji, the removal and continuing management of sand and gravel that now choke the Sigatoka river will result in an increase in fish stocks and variety of aquatic life, more efficient flushing of biological pollution from the river water and reduce the annual threat of flooding.